Space and astronomy news

When it comes to the current era of space exploration, one of the most important trends is the way new technologies and processes are lowering the cost of sending crews and payloads to space. Beyond the commercial space sector and the development of retrievable and reusable rockets, space agencies are also finding new ways to make space more accessible and affordable.

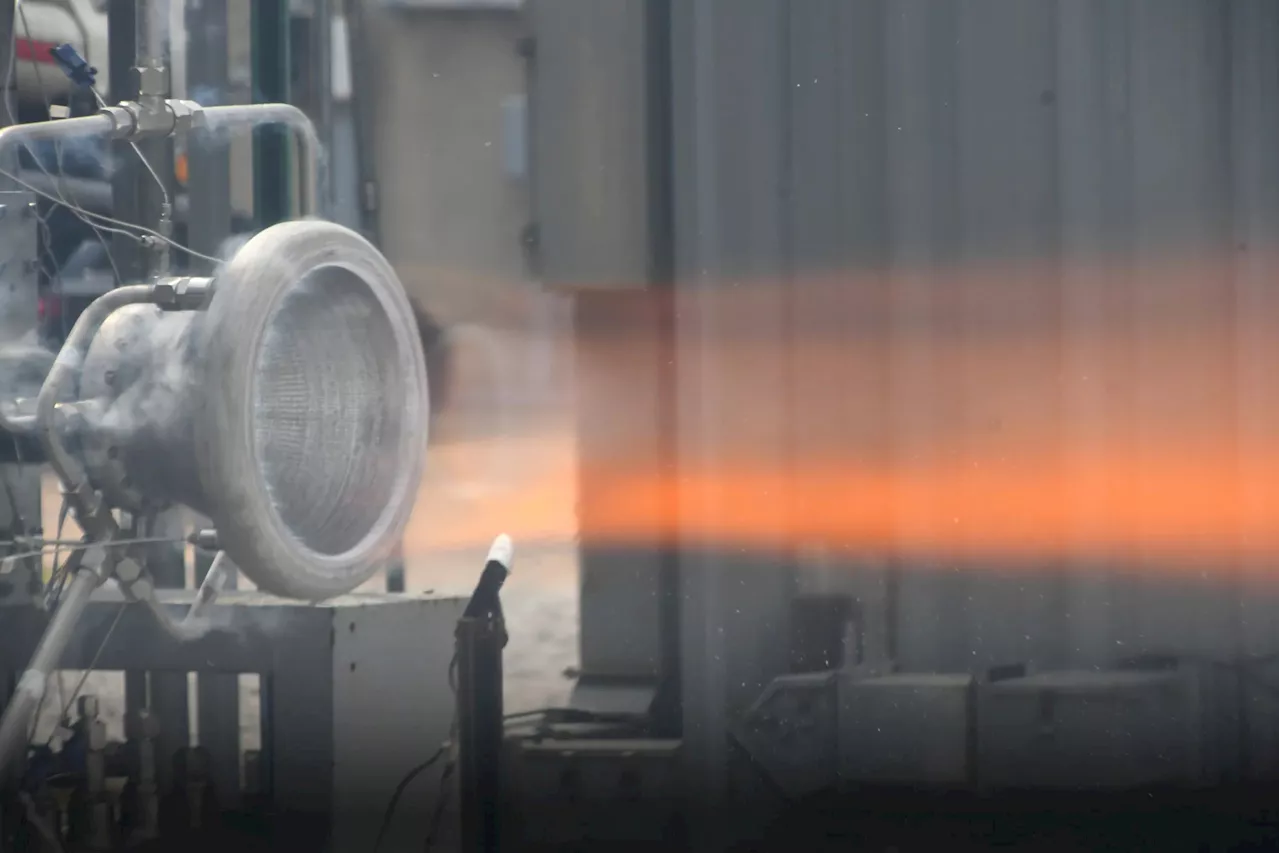

Compared to other metals, aluminum has a lower density and can enable high-strength, lightweight components. However, with conventional manufacturing, a rocket nozzle may require a thousand individually joined parts. This makes aluminum impractical since it has a low tolerance to extreme heat and a tendency to crack during welding.

“Industry partnerships with specialty manufacturing vendors aid in advancing the supply base and help make additive manufacturing more accessible for NASA missions and the broader commercial and aerospace industry. This test series marks a significant milestone for the nozzle. After putting the nozzle through the paces of a demanding hot-fire test series, we’ve demonstrated the nozzle can survive the thermal, structural, and pressure loads for a lunar lander scale engine.

France Dernières Nouvelles, France Actualités

Similar News:Vous pouvez également lire des articles d'actualité similaires à celui-ci que nous avons collectés auprès d'autres sources d'information.

NASA tests 3D printed nozzle for deep space missionsInteresting Engineering is a cutting edge, leading community designed for all lovers of engineering, technology and science.

NASA tests 3D printed nozzle for deep space missionsInteresting Engineering is a cutting edge, leading community designed for all lovers of engineering, technology and science.

Lire la suite »

College students create 3D printed home that took only 15 months to build for $250,000This 3D printed home took only 15 months to build from start to finish with a price tag of $250,000. This affordable housing solution is the work of a team of local college students.

College students create 3D printed home that took only 15 months to build for $250,000This 3D printed home took only 15 months to build from start to finish with a price tag of $250,000. This affordable housing solution is the work of a team of local college students.

Lire la suite »

Could Woodbury University students' 3D-printed home be a solution to LA's housing crisis?With half the workload, students at Woodbury University designed a sustainable 425-square-foot home, made entirely by cement spraying robots.

Could Woodbury University students' 3D-printed home be a solution to LA's housing crisis?With half the workload, students at Woodbury University designed a sustainable 425-square-foot home, made entirely by cement spraying robots.

Lire la suite »

New 3D-printed tumor model enables faster, less expensive and less painful cancer treatmentAn international team of interdisciplinary researchers has successfully created a method for better 3D modeling of complex cancers. The University of Waterloo-based team combined cutting-edge bioprinting techniques with synthetic structures or microfluidic chips.

New 3D-printed tumor model enables faster, less expensive and less painful cancer treatmentAn international team of interdisciplinary researchers has successfully created a method for better 3D modeling of complex cancers. The University of Waterloo-based team combined cutting-edge bioprinting techniques with synthetic structures or microfluidic chips.

Lire la suite »

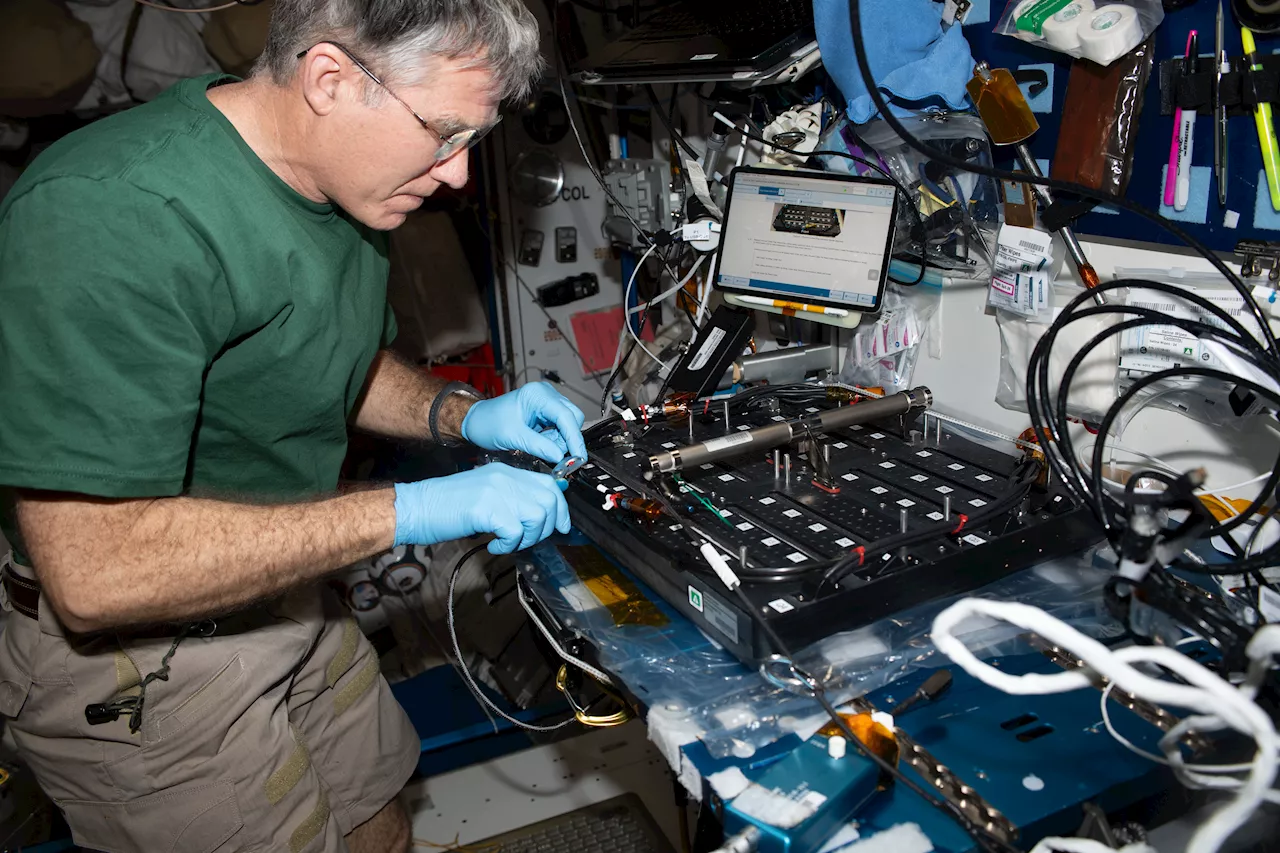

Join NASA to Discuss High-Rate Laser Comms Demo, Space Station ScienceNASA will host a media teleconference at 11 a.m. EDT Thursday, Oct. 26, to discuss a laser communications system and new research to understand the

Join NASA to Discuss High-Rate Laser Comms Demo, Space Station ScienceNASA will host a media teleconference at 11 a.m. EDT Thursday, Oct. 26, to discuss a laser communications system and new research to understand the

Lire la suite »